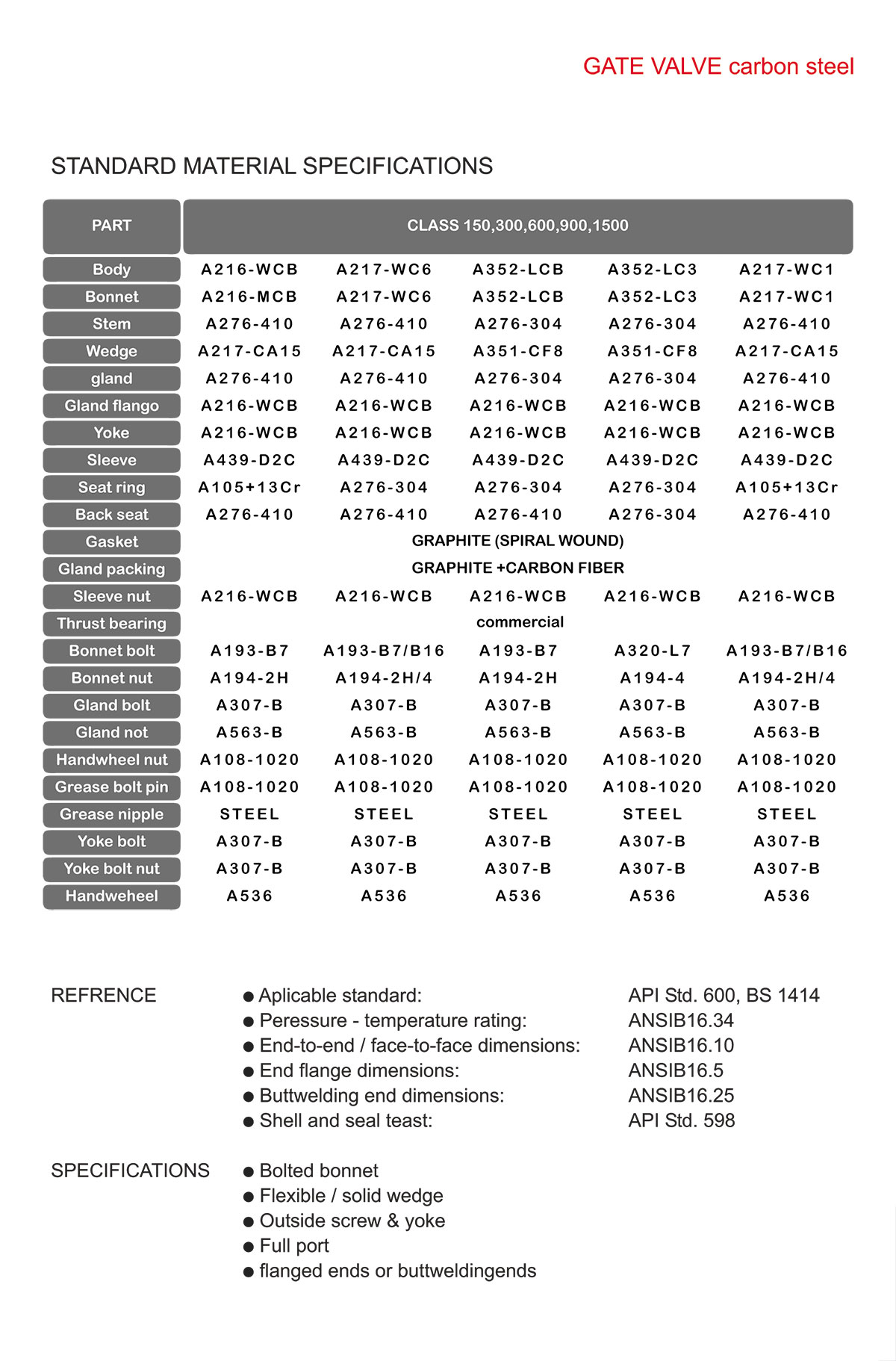

Gate valve

These valve are made in accordance with all international standards and...... from 150 LB to 1500 LB and PN ,as well as in an angle form of the best quality cast steel and stainless steel in the body and seat .They can be set up manually and automatically.

Reviews

There are no reviews yet.