CHECK VALVES

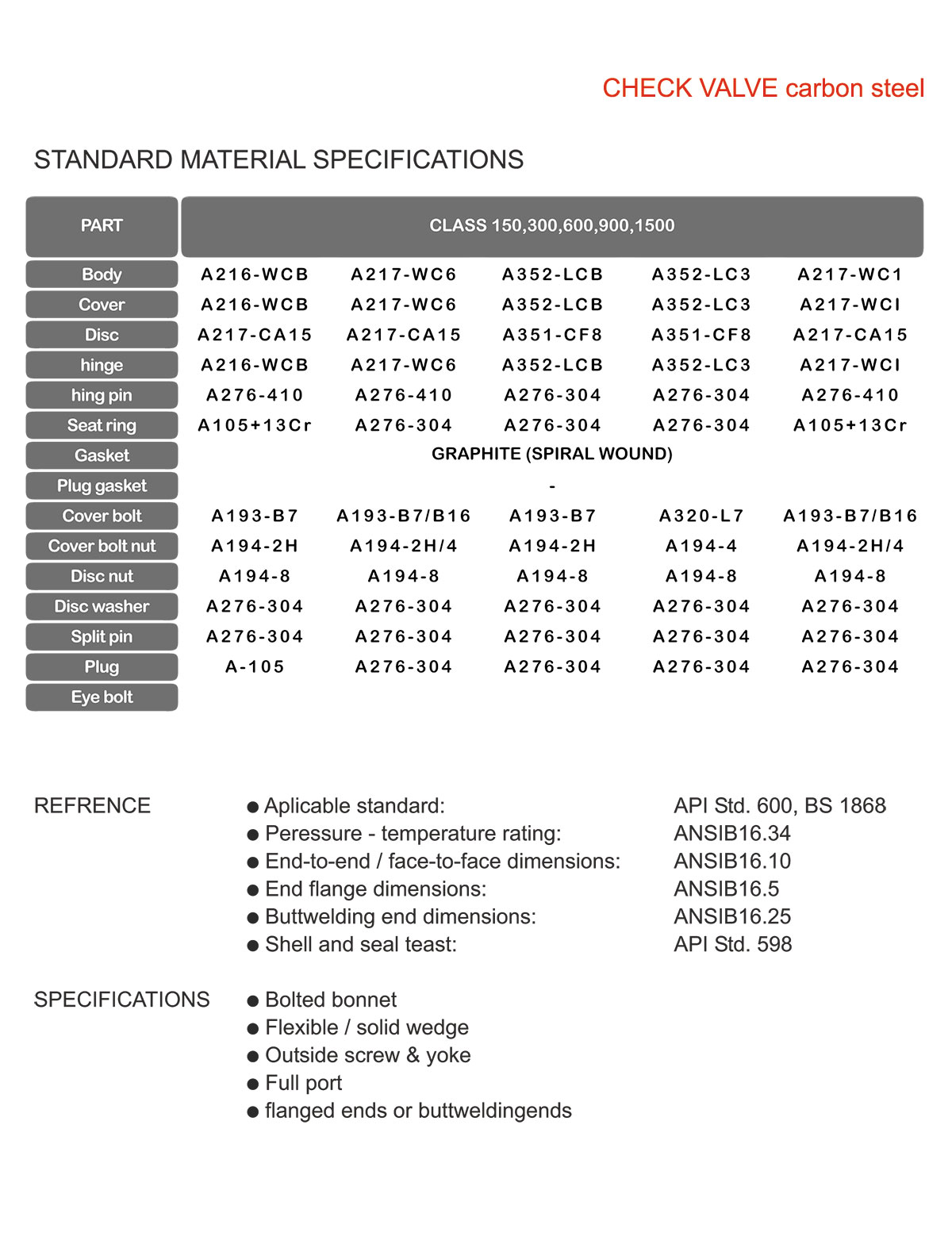

There are swing type , lift check valve ,and diaphragm for different working pressure and the material are steel , Carbon,and stainless steel according to the table below.These valves are designed in a way that when the valve is closed ,there is no sudden increase in pressure and water hammer.

Reviews

There are no reviews yet.